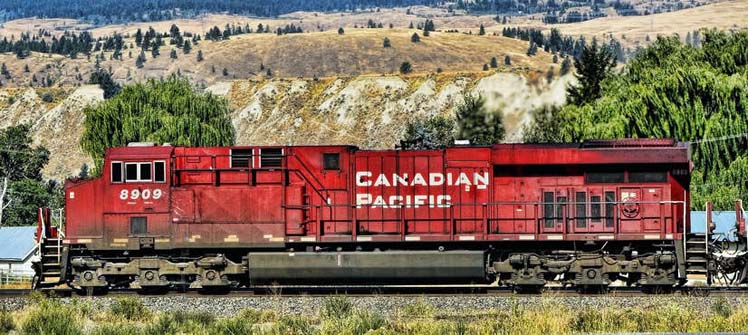

on Oil Trains

North America - Last year, Canada exported a record amount of tar sands oil to the U.S., despite low oil prices leading to major losses once

again for the struggling tar sands industry.

That achievement required a big bump in hauling oil by rail, with those daily volumes in late 2018 more than double the previous record in 2014 during the

first oil-by-rail boom.

Canada's oil industry essentially has reached its limit for exporting oil into the U.S. through pipelines.

That's why it's turning to rail to export more and more oil, but as an ever-increasing number of oil trains hit the tracks of North America, expect more

accidents and oil spills to follow.

If Canada can open up new pipeline capacity, this scenario may change.

However, Enbridge recently announced its Line 3 pipeline replacement will be delayed until at least the second half of 2020.

That means if Canadian tar sands companies want to increase exports, they will have to move that oil by rail.

Conoco Phillips chief financial officer Don Wallette Jr. recently confirmed this reliance on oil trains to the Wall Street Journal, "The intention is to

bridge us over to the next major pipeline expansion, so a few years."

This could result in a near doubling of the current record volumes of Canadian crude moving by rail.

Trains potentially could haul over 600,000 barrels per day (bpd) in the next two years, an outcome I predicted four years ago when the Canadian industry was

moving only 150,000 bpd of oil by rail.

To put these volumes in perspective, the Enbridge Line 3 pipeline will have a capacity of 760,000 bpd.

Oil trains amount to a veritable pipeline on wheels.

To help move things along, the Alberta government announced it will spend $3.7 billion to lease 4,400 rail tank cars.

The province, heavily reliant on the tar sands industry, hopes to move an additional 120,000 bpd by mid-2020.

There haven't been many details on the Alberta plan made public, so it isn't clear if the government will be moving an additional 120,000 bpd or if this will

contribute to the estimated 600,000 bpd total.

This rapid ramp-up of moving crude by rail is causing congestion in the overall Canadian rail system, which likely will affect oil-by-rail volumes as

well.

If the oil and rail industries do end up moving 600,000 bpd or more of oil by train, one thing is for certain, accidents will increase.

More Trains + Weak Regulations = More Accidents

In February, just as Alberta was announcing its oil-by-rail business plans, Canadian National Railway (CN) was dealing with an oil train derailment that caused

a roughly 264,000 gallon oil spill in Manitoba.

That train was using the new model of retrofitted rail cars, which were promoted as safer for oil transport.

However, those supposedly safer rail cars did little to prevent a major oil spill, much as in 2018 when a train full of Canadian oil derailed in Doon, Iowa,

and spilled 230,000 gallons of oil into a river's floodwaters.

As detailed on DeSmog, existing regulations ignore many of the risks of moving oil by rail.

That means as oil volumes increase, we should expect derailments to increase too.

And while the rail industry likes to tout its safety record, 2018 was not a good year for the Canadian rail industry, which experienced an increase in

accidents.

The big increases in moving oil by rail will push the Canadian rail system to its limits over the next two years.

Oil Train Activism Continues

While Canadian oil train volumes are breaking records, those numbers could be even higher if not for the efforts of activists effectively blocking new

oil-by-rail infrastructure in North America.

Activists have blocked many proposed projects on America's West Coast and expansion efforts to the East Coast as well.

Local municipalities for port cities have passed laws banning new fossil fuel infrastructure, which effectively blocked new oil-by-rail facilities in Portland,

Oregon, and Baltimore, Maryland.

The Portland law withstood multiple legal challenges by the oil industry.

Despite these efforts, oil-by-rail volumes in America were 88 percent higher in October 2018 compared to the previous October.

However, volumes remain below the peaks achieved in the first U.S. oil-by-rail boom, fueled by skyrocketing oil production in the Bakken Shale region of North

Dakota.

This resurgence in oil-by-rail in America has led to activists and local communities pursuing new efforts to address the growing risks as oil trains roll

through their cities and towns.

Despite the ban on new infrastructure in Portland, Oregon, one company is expanding its oil-by-rail off-loading operations using permits that were approved

before the ban went into place.

The oil is being shipped into Portland and then loaded onto ships for export.

While activists were unable to prevent the expansion, they say they are keeping tabs on the activity.

Just to the north of Orgeon, the state of Washington is considering a bill that would create a vapor pressure limit of 9 pounds per square inch for any oil

off-loaded and stored in the state.

A similar regulation was initiated at the federal level after the New York State Attorney General filed a petition in 2015.

That regulation, however, has gone nowhere since the beginning of the Trump administration.

Reducing the vapor pressure of oil, which essentially lowers the volatility, reduces the chance that it will ignite in a derailment.

Despite these efforts, municipalities generally have very little ability to regulate the movements of oil by rail through their communities.

As a result, Canada will be exporting large volumes of oil into and across the U.S. to refineries and ports for later export, despite the opposition of many

communities along the rails.

The oil and rail industries have been lucky that none of the recent oil train derailments have occurred in populated areas.

With the lack of stringent safety regulations and the boom in oil train traffic expected for the next few years, the estimated 25 million people living within

the oil train blast zones along North American railroads will be hoping that lucky streak doesn't run out.

Justin Mikulka.

provisions in Section 29 of the Canadian

Copyright Modernization Act.