My initial introduction to railways in Switzerland begins in an early Archive article about the Jungfraubahnen, three railways which operate in the Bernese Oberland region. One railway begins at Interlaken, connecting with two others with the last terminating at an elevation of 11,300 feet (3,444 metres) at the Top of Europe. If you missed that story you can find it on the Archive page. For a brief description about the country known as Switzerland click on the logo of the Swiss cow to the right.

Dampfbahn Furka Bergstrecke AG (DFB)

Geschäftssitz Oberwald

Postfach 6490

Andermatt

Switzerland

N46.595345 E8.500870

(Realp depot)

(Realp depot)The problem with Switzerland is, it's a wee bit hilly. This doesn't seem to bother the cows much, but for transportation systems such as railways it's a big challenge. People, produce, and goods need to move, so this means in Switzerland, almost as much going up and down as moving horizontally it seems. Adhesion railways are restricted as to how steep a hill they can climb, perhaps a 4 percent grade being about the top limit. This is a severe limitation in Switzerland, it's those hills again. To overcome this limitation the Swiss developed their first rack railway on Mount Rigi (the Rigi Bahn) in 1871. The rack, there are several designs such as Riggenbach, Strub, Abt, Lamella, and Locher, lies between the two running rails and is engaged by a cogwheel on the locomotive. A tremendous solution! Now a railway can climb grades as steep as 50 percent, which is the safe maximum.

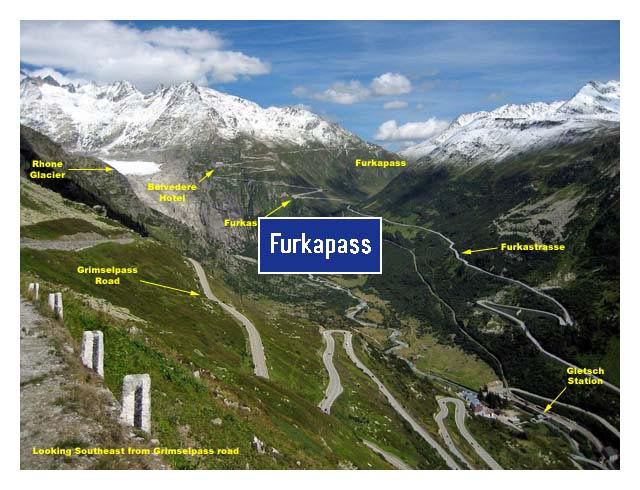

The Dampfbahn Furka-Bergstrecke rail line climbs over the Furka Pass between Realp and Oberwald. This simplified grade chart shows the elevations.

In 1907 and 1908 someone decided to build a railway between Brig and Disentis. The route would take it over the Furka Pass with a summit of 2,163 metres (7,097 feet). Like other railways of the time, it would be narrow, 1,000 millimetre (3 feet 3 3/8 inch) gauge. This was to be a rack and adhesion railway, only the steepest sections would use a rack. In 1911 construction was commenced by the Furka Railway Company so that by 1914 steam engines were climbing the west slope of Furka Pass to Gletsch. By 1915 the Furka Summit Tunnel had been completed. A year later the first Steffenbach bridge, which was originally a stone viaduct, was destroyed by an avalanche. Hence the current steel bridge, built in 1926, is folded up each fall to avoid the winter avalanches.

The operating expenses to keep this line running, especially in winter, must have been a extreme burden for by 1923 the railway was bankrupt. Enter a new company, the Furka Oberalp Bahn (FO). This company rebuilt the line between Gletsch through Andermatt to Disentis and began steam powered operation in 1926. In 1930 the Glacier Express was born and the first trip all the way from Zermatt to Saint Moritz was carried out. By 1942 the line was electrified between Brig and Disentis so there was no further need for steam powered rack locomotives. The HG 3/4 steam engines were shipped to French Indochina, what is now Vietnam in 1947, but a few steamers remained until the last steam run in 1968 from Brig to Disentis.

In 1973 construction of the Furka Base Tunnel would lead to the abandonment of the route over Furka Pass. By 1982 the Furka Base Tunnel was in regular use, there was no need to operate a rack railway over the pass any longer and it was abandoned.

Over time the Furka Oberalp Bahn (FO) disappeared as it was amalgamated with the BVZ Zermatt Bahn (BVZ) to become the Matterhorn Gotthard Bahn (MGB) in 2003. In 1990 a group of people formed the Dampfbahn Furka-Bergstrecke (DFB) and obtained an operating permit from the Swiss Federal authority. The steam engines were retrieved from Vietnam and arrived in Hamburg where HG 3/4 No. 1 was shipped on to the Meiningen Works for rebuilding. In 1993 HG 3/4 No. 1 was named "Furkahorn" and put into service.

From here on it was all uphill for this group, literally, pardon the pun. Train service was provided between Realp to Tiefenbach haltestelle at first, then extended to Furka. Steam engine No. 2, "Gletschhorn", came online, a new depot in Realp was completed, a gap in the tracks at the Muttbach grade crossing was closed, and on 30 Sep 1999 the first official steam train arrived next to Gletsch station which is located on the other side of a small stream fed by the Rhone Glacier. The following summer, on 24 Jul 2000, regular service was incorporated between here and Realp.

By 2001 the DFB had 3 steam engines in operation running passenger trains between Realp and Gletsch.

The volunteers who were financing, building, running, and maintaining this railway were not yet done. 2008 saw a plan to complete the entire route over Furka Pass from Realp, Tiefenbach, Furka, Gletsch, and all the way through to Oberwald.

On 12 Aug 2010 the line was complete when the official train arrived at Oberwald. Trains can only be run, on average, 70 days per year. Every fall Steffenbach bridge is folded, tunnel doors are closed, and the railway shuts down for the winter. Snow conditions on Furka Pass make it financially impossible to operate year-round. But that's fine, we wouldn't want to see another insolvency. Lets hope this railway continues to prosper. If Swiss determination and hard work are any indication this railway will do just fine thank you.

Bridges fascinate people all over the world. There are countless examples of famous bridges everyone is likely to have heard of, or read about, at some point in their lives. One further example of consummate bridge building to add to the list is the Steffenbach bridge on the Furka cogwheel steam railway line.

A folding mechanism that protects against avalanche damage is what makes this bridge so special. This was developed to protect the bridge after the first two conventional bridge designs (1913 and 1915) actually collapsed or were damaged so badly by avalanches that the track became unusable. The civil engineer Rudolf Dick therefore designed a steel span bridge without any pylons to be built over the stream bed. The design gives avalanches the smallest possible area to attack.

Comprised of three-sections the bridge is dismantled in autumn and re-erected in spring. When the bridge is dismantled, the two middle sections are folded down and lowered at the edge of the ravine on large hinges attached to the end of a fixed bridge section. These are then pulled back to firm ground on top of the tracks. The bridge then "hibernates" in this position from October until May. When the snow is cleared on the line in spring, the bridge is re-erected. Depending on the prevailing weather conditions, it takes between 12 and 15 technicians about 5 to 8 hours to complete the demanding task.

Two Rotzler HK 075 winches have been moving and positioning the several-tonne bridge sections since 1990. This has proved to be a considerable convenience in comparison to the former manual winches, which took 20 men and a lot of hard work to operate. The hydraulic winches each feature a 153 metre long, 16 millimetre wire rope. The ropes are used with a pulley system to move the bridge sections. The smoothness and reliability of the winches are of key importance for the construction team, after all, the bridge sections have to be positioned very accurately.

After 17 years of unfailing service, the winches were taken to the Rotzler plant in Steinen for a general overhaul prior to the yearly bridge dismantling operation in October. The winches were inspected by Rotzler's After Sales Service and subsequently overhauled to ensure their continued safe operation at the Steffenbach bridge.

The Swiss locomotive classification system was created in 1902. It does not classify locomotives by wheel arrangement such as the Whyte system but is more about specifying types and series. Letters and numbers designate first the class, then the traction type, the number of drive axles, and the total number of axles, followed by the series, which is a Roman numeral superscript. For example the HG 4/4 class is explained below:

H = Locomotive with rack rail operation.

G = Narrow gauge locomotive for adhesion operation.

4 = Driving axles.

4 = Total number of axles...

and in this case there is no second or further series.

| Class | Meaning |

| A | Standard gauge locomotive with Vmax over 80 kph |

| B | Standard gauge locomotive with Vmax from 70 to 80 kph |

| C | Standard gauge locomotive with Vmax from 60 and 65 kph |

| D | Standard gauge locomotive Vmax from 45 to 55 kph |

| E | Shunting locomotive or steam tank engine |

| F | Electric locomotive (only until 1920) |

| G | Narrow gauge locomotive for adhesion operation |

| H | Locomotive with rack rail operation |

| R | Locomotive with higher cornering speed compared with A and Vmax at least 110 kph |

| T | Tractor |

| Type | Meaning |

| a | Battery (Accumulator) |

| e | Electric |

| f | Radio control (unofficial extension) |

| h | Rack rail drive (for rail cars and tractors) |

| m | Fuel (Diesel, Gas turbine) |

For some unknown reason there is no traction type for steam locomotives.

The DFB has three distinct types of steam rack locomotives. The two types shown above on the left, HG 2/3 (0-4-2T) and HG 3/4 (2-6-0T), are currently operational as is the rebuilt HG 4/4 (0-8-0T) number 704. A time consuming and expensive prospect but obviously a labour of love. The majority of these engines were constructed by Schweizerische Lokomotiv und Maschinenfabrik (SLM) which was founded in 1871. Below you will find a roster of the DFB steam locomotives.

Locomotive numbers 3 and 5 are not yet assigned, apparently, for reasons unknown.

The HG 4/4 engines were originally constructed by Schweizerische Lokomotiv und Maschinenfabrik (SLM) in Winterthur. Five of these engines were purchased by France beginning in 1924 and shipped to the Chemin de fer de l'Indochine (CFI) in Indochina, their colony at the time, but now known as Vietnam. In 1929 the Machine factory of Esslingen in Germany supplied two more of these locomotives built under license from SLM as war indemnification. Later in 1949 all locomotives received new numbers with the prefix VHX (Vietnam Hoa Xa) under a Vietnamese administration. They operated in the southern part of the country connecting the coast with a village named Da Lat 5,000 feet above sea level. The railroad line suffered considerably during the Vietnam War, and with its end the locomotives fell into disrepair. Then in 1983 after several years of negotiations a Swiss group purchased and repatriated two HG 4/4 engines and one frame. They were shipped to the DFB workshop in Chur, Switzerland, where they are to be rebuilt. Once operational they will be the most powerful cogwheel steam locomotives in Europe, and will represent together with the original locomotives of the Visp Zermatt Bahn and the Furka Oberalp Bahn, a unique testimony to Swiss engineering. (HG 4/4 number 704 is now operational.)

The HG 4/4 locomotives are unique in that the cogwheel and adhesion drive mechanisms are separated. This is known as the "System Winterthur". Two low pressure cylinders drive two cogwheels with an intermediate reduction gear. These are adjustable in height and can be easily adapted to the wear of the adhesion drive wheels. The adhesion drive is the same as that commonly used on steam engines with the cylinders on the outside. When running on adhesion trackage only, the lower outside cylinders, i.e. the high pressure cylinders, receive the live steam. Traveling on rack sections the locomotive works in the compound mode, i.e. the live steam after expansion in the high pressure cylinders is directed to the low pressure cylinders which drive the cog wheels. This allows for optimal power distribution and control. This type of driving mechanism was developed by SLM with great success and became part of many export orders.

Built 1913

Builder SLM

Boiler Pressure 14 bar (203 psi)

Maximum Speed Adhesion 30 kph (19 mph)

Maximum Speed Rack 15 kph (9 mph)

Length 8,750 mm (29 feet)

Weight Operating 44 tons

Towing Capacity 60 tons

Fuel Coal

Repatriated from Vietnam in 1990.

Built 1913

Builder SLM

Boiler Pressure 14 bar (203 psi)

Maximum Speed Adhesion 45 kph (28 mph)

Maximum Speed Rack 20 kph (12 mph)

Length 8,750 mm (28.7 feet)

Weight Operating 44 tons

Towing capacity 60 tons

Fuel Coal

On loan to DFB from Furka Oberalp Bahn.

Built 1902

Builder SLM

Boiler Pressure 12 bar (174 psi)

Maximum Speed Adhesion 30 kph (19 mph)

Maximum Speed Rack 15 kph (9 mph)

Length 7,624 mm (25 feet)

Weight Operating 31.7 tons

Towing Capacity 40 tons

Fuel ?

Gift of Herald School House Chur.

Built 1906

Builder SLM

Boiler Pressure 12 bar (174 psi)

Maximum Speed Adhesion 30 kph (19 mph)

Maximum Speed Rack 15 kph (9 mph)

Length 7,624 mm (25 feet)

Weight Operating 31.7 tons

Towing Capacity 40 tons

Fuel Oil

On loan from Matterhorn Gotthard Bahn.

Built 1914

Builder SLM

Boiler Pressure 14 bar (203 psi)

Maximum Speed Adhesion 45 kph (28 mph)

Maximum Speed Rack 20 kph (12 mph)

Length 8,750 mm (28.7 feet)

Weight Operating 44 tons

Towing Capacity 60 tons

Fuel Coal

Repatriated from Vietnam in 1990.

Built 1923

Builder SLM

Boiler Pressure 14 bar (203 psi)

Maximum Speed Adhesion 40 kph (25 mph)

Maximum Speed Rack 15 kph (9 mph)

Length 8,950 mm (29.3 feet)

Weight Operating 45 tons

Towing Capacity 75 tons

Fuel Coal

Repatriated from Vietnam in 1990.

Built 1930

Builder SLM

Boiler Pressure 14 bar (203 psi)

Maximum Speed Adhesion 40 kph (25 mph)

Maximum Speed Rack 15 kph (9 mph)

Length 8,950 mm (29.3 feet)

Weight Operating 45 tons

Towing Capacity 75 tons

Fuel Coal

From Vietnam in 1990 but not rebuilt.

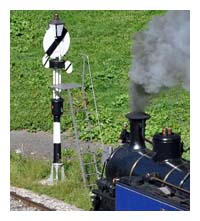

This unique electro-mechanical signal, known as a Hippsche Wendescheibe, can be found about a kilometre from Realp along the DFB's line over Furka Pass. The name seems to translate to Hipp's turning wheel. It was invented in 1862 by a clock maker named Matthew Hipp specifically for Swiss railways.

The signal has only two indications, "Stop" and "Free Journey" (clear to proceed).

It is comprised of a large red disk with a white diagonal bar on one side while the other side of the disk is white with a black diagonal bar. Sitting astride, and on top of this large disk, is a lantern with four faces, one of which is red matching the red face of the large disk, the other lantern faces are white. Below the large disk are two small white discs with black diagonal lines mounted to either side of the mast. All these discs and lamp ride on a circular support on top of the signal mast which can be rotated. In the "Stop" indication the red lantern face and red disk with white bar face an oncoming train. Since the two smaller white disks with black stipes are offset by 90 degrees to the large red disk they present their edge to an oncoming train.

For a "Free Journey" (clear to proceed) indication, all disks are rotated clockwise by 90 degrees so that the red disk presents its edge and white lantern face while the two small disks display their white faces with diagonal black bar.

Since the device only turns clockwise it must now make a 270 degree turn to return to the original "Stop" indication.

Now, to do all these rotations, the signal is powered by a weight located in the mast connected by a chain to gears which rotate the signal. The weight will provide enough momentum for 200 rotations then it must be manually pulled up again. Apparently this duty was performed daily by a station employee or track guard. The rotating portion of the signal is locked in position by an electromagnet which is powered by a battery. The command to rotate is transmitted by a low voltage electrical pulse from a distance. This triggers the electromagnet to release the locked turning wheel which is then rotated by the tension from the hanging weight.

Another unique feature of this railway is the Furkastrasse grade crossing at Oberwald. It employs, not only the typical automatic crossing gates, but a retractable rack section. The mechanism was built and assembled off-site by Baumgartner AG Münchenbuchsee, near Bern, then transported to the Furkastrasse by a truck. Comprised of cast concrete and steel the mechanism weighs 36 tons. A large crane positioned it over the road and the installation was completed the night of 7 May 2010.

When an approaching train activates the system, crossing warning gates first swing down in a typical manner. Once the gates are in the barricade position the rack section, whose teeth were level with the road surface, is automatically raised to the proper height so it may be engaged by the cogwheel of a passing locomotive.

With the installation of this device trains can now run the entire route from Oberwald to Realp for the first time in nearly 30 years.

The operation of this retractable rack grade crossing and gates may be viewed in this YouTube video.

video.

The Dampfbahn Furka-Bergstrecke folder for the 2011 season may be seen here. Visit the Dampfbahn Furka-Bergstrecke website

for up-to-date information.

for up-to-date information.Fast forward to 2021 and a lot has changed at Realp while the railway has progressed tremendously since the photos with this article were taken in 2011. The two stall concrete roundhouse at Realp now has five stalls while a large new storage shed for DFB equipment has also appeared there. Another big ticket item is the rebuilding of HG 4/4 number 704 shown earlier in the locomotives section. It is now in service with the requirement that it must always face uphill, one would assume this is to keep water over the crownsheet. As a result a manual turntable has been added at Furka so the engine may be turned on its route between Realp and Oberwald. For example it would depart Realp facing upgrade to Furka, turn on the table, then back downgrade through the summit tunnel (the summit tunnel is virtually level) to Gletsch and Oberwald where it would be turned for the return uphill climb back to Gletsch and Furka, turned once again, then proceed downgrade to Realp. That's a lot of turning for just a 22 mile (36 kliks) round trip. I like it!