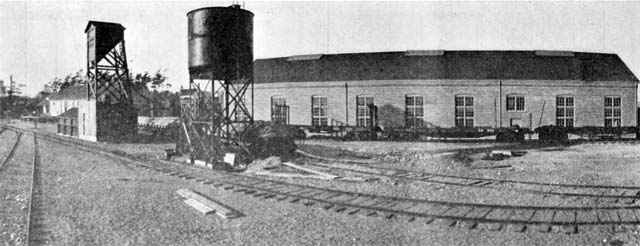

The recently completed group of buildings forming the Esquimalt and Nanaimo Ry. terminal plant at Victoria West, B.C., comprises a locomotive house, machine shop, car repair shop, boiler, engine houses, and store, etc.

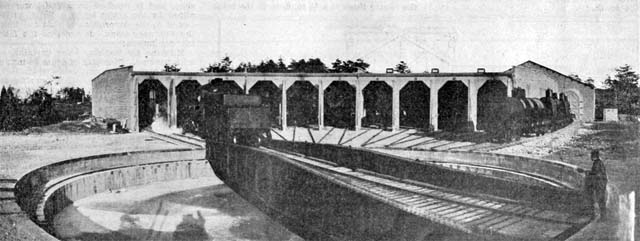

The locomotive house has 10 stalls, each 13 feet 7 inches at the front, 26 feet 5 inches at the back and 90 feet deep. The walls are of 13 inch brick work on strong concrete foundations, and the roof is of timber construction covered with felt and gravel. The usual locomotive pits are provided, together with one drop pit 7 feet wide. The walls of these are of 10 inch concrete, to which is fastened, by means of anchor bolts, the 6 by 12 inch timbers carrying trackage. For a width of 3 feet all around the pit, 3 inch planking is spiked, the intervening floor space being finished off with cinders.

The machine shop is 68 by 112 feet and 18 feet high to the under side of roof truss, and is provided with two locomotive pits and one drop pit similar in construction to those in locomotive house. The shops abut end-on to the back of the locomotive house, one track entering from the end stall, and one from the outside of the locomotive house, thus providing outgoing and incoming tracks over turntable. The roof is pitched and is carried by six timber trusses at 16 feet centres, these are supported on brick piers standing out 4 1/3 inches from the 13 inch walls. Good lighting has been secured by three large skylights on the roof, together with ample sidelights, two windows being fixed in each bay. Bench accommodation has been supplied for the fitters, and the whole floor has been planked over. A width of about 36 feet extending the length of the building, has been reserved for the installation of machinery tools, which are now being fixed, and include: 18 foot wheel lathe, 16 foot Bertram lathe, Bertram gap lathe, 20 foot gap lathe, 8 foot screwing machine, small Bertram lathe, a large and a small drill, wheel press, planer, and shaper. The main shafting will be bracket fixed to the brick piers, and the counter shafting to the underside of the roof trusses.

The blacksmith and boiler shop is a continuation of the machine shop, partitioned therefrom by a 9 inch brick wall. In it will be located the steam hammer, two circular and one oblong forge, together with one set of shears and one set of rolls. This building is 32 by 68 feet.

The engine room and boiler room are located in the angle formed by the two main buildings, the former being 31 feet 10 inches by 20 1/3 feet and the latter 45 2/3 feet by 19 1/3 feet. The engine provided is 76 h.p. and of the tandem compound type. The air compressor is of the imperial cross compound steam driven type X, made by the Ingersoll-Rand Co. Two 100 h.p. standard CP locomotive type boilers, carrying 130 pounds pressure, are being installed. They are equipped for fuel oil, which will be pumped to the burners from a 4 by 6 foot circular auxiliary tank, located underground outside the building. This tank, in turn, will be supplied by gravity from the service tank located near the turntable.