Montreal - CP Rail is already planning for next year's track upgrading and construction program.

The railway is spending $25.7 million to purchase 2.4 million wood cross ties from 162 lumber companies across Canada.

British Columbia forests supply almost all of the wood for the railway's cross ties. Five softwood tree species are used, douglas fir, western larch, western hemlock, ponderosa pine, and lodgepole pine.

The size of tie varies slightly depending on where they will be installed. On the main line, softwood ties 2.4 metres long, 22.8 centimetres wide and 17.7 centimetres thick (8 feet x 9 inches x 7 inches) are used.

Special Uses

But in curves on heavily-used sections of track, 2.7 metre-long (9 foot-long) hardwood ties are used. The hardwood is stronger and the longer tie spreads the load over a greater area to reduce stress on the track.

The smallest sized ties are used on lightly travelled main lines, branch lines, and sidings. These are 2.4 metres long, 20 centimetres wide, and 15 centimetres thick (8 feet x 8 inches x 6 inches).

With 3,000 ties per mile of track and around 22,000 miles of track across Canada, the railway has a big stake in ties. So CP Rail keeps a close watch on the product, at all stages.

Technical inspectors check quality both before and after the ties are seasoned and treated with preservatives. Samples of the preservatives used and of the wood after treatment are tested to ensure adherence to specifications.

New Wood Ties Go Through an Expensive Treatment Process

It costs almost as much to prepare new wood cross ties for use by the railway as it does to buy them.

CP Rail is buying 2.4 million tie's, cost, $25.7 million, plus another $2 million per month for the year-long seasoning and treatment required. That procedure will be carried out at seven plants across Canada.

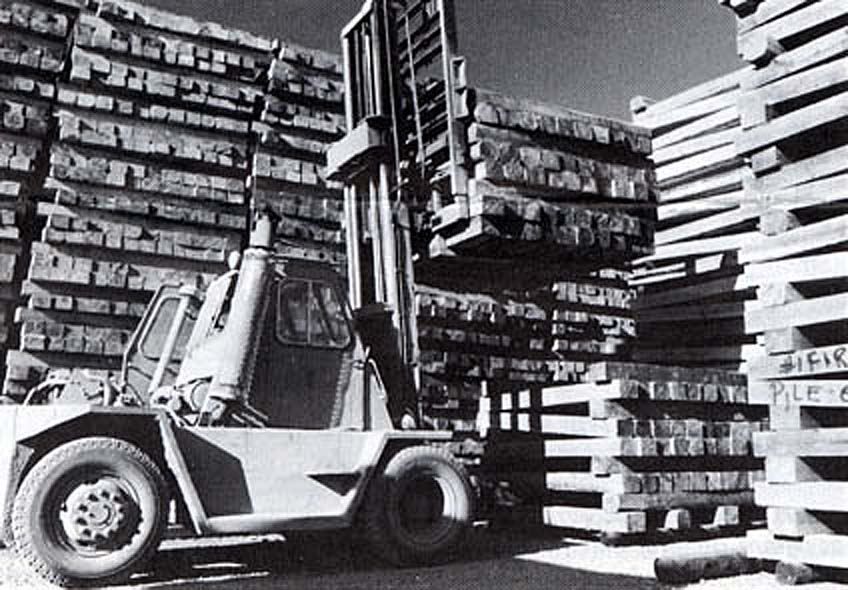

At the plants, the ties are stacked seven metres (20 feet) high to dry out for eight to twelve months. Then holes are drilled in the ties where spikes will be driven to secure the rails to them.

Next, the ties go through an incising mill. Small cuts are made in the wood to facilitate absorption of preservatives during the treatment process.

Finally, the ties are inserted into air-tight cylinders 50 metres (165 feet) long and 2.1 metres (7 feet) in diameter. The cylinders can hold around 1,000 ties.

Special Mixture

Air is pumped into the ties at 40 to 75 pounds per square inch (p.s.i) pressure. A pressure mixture of creosote and bunker oil is applied under 175 p.s.i.

The treatment process takes about seven hours to complete. Then the ties are ready for use.

The treatment plants are located at Ashcroft and New Westminster B.C., Cochrane Alberta, Thunder Bay and Trenton Ontario, Delson Quebec, and Truro Nova Scotia.

(because there was no image with original article)

*2. Original news article image replaced.

(usually because it's been seen before)

under the provision in Section 29

of the Canadian Copyright

Modernization Act.