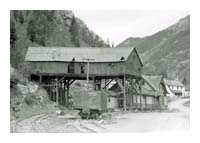

This photo immediately grab's ones attention when first seen. It's obviously a shot of a Rio Grande Southern depot but what's that structure directly behind the depot? It looks like a mine, but that close to the depot? Peculiar.

A fair amount of internet research turned up the following information. The building is the Belmont-Wagnor Mining Company's Alta Lakes aerial tramway terminal, known as the tramhouse. In 1878 Gold was found in the Alta vein of the Gold King Basin at 12,000 feet elevation. In 1898 miners drove the Black Hawk tunnel 9,000 feet into Silver Mountain to intersect the Alta, St. Louis, and Bessie veins, providing access directly to a new 20 stamp mill that also took the name Bessie. Output soared, and the company town of Alta grew around the new mill. In 1909 workers constructed a two mile aerial tramway that dropped more than 1,800 feet to deliver concentrate directly from the Bessie mill to the tramhouse beside the Rio Grande Southern depot at Ophir. The Belmont-Wagner Company acquired the Bessie mill in 1918 hence then current name for the tramhouse.

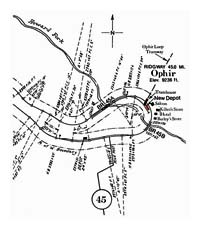

Above are two examples of typical aerial tramways of the period and a map showing the location of track, Ophir depot, and the tramhouse beside the depot.

The mines that dotted the high, steep, and rugged San Juan Mountains were reliant on the construction of aerial tramways for transporting ore, supplies, and personnel. With development of the wire rope in the early 19th century, miners finally had the technology necessary to adapt rope tramways to mining activities. Developed in Europe, the first wire ropes were made of a series of small wires hand woven around a hemp core. As early as 1834 a small aerial mine tramway was operating in Austria. To support the cable, towers were erected at appropriate locations usually no more than 250 feet apart. Attached to the top of the towers were grooved pulleys or rollers through which the cable ran. Thus, much like a modern ski-lift, the cable moved in an endless circle. Permanently attached to the cable at distances of about 50 feet were steel arms or clips with ore buckets suspended below. Since most loads moved in a downhill direction, gravity usually provided enough momentum to keep the tramway moving. In this fashion, traveling at 200 feet per minute, and carrying 150 pounds of ore per bucket, 36,000 pounds per hour could be delivered at a cost of twenty to forty cents per ton mile. The aerial tramway proved to be the cheapest way to move ores on steep Colorado mountain sides.

The next two photos show Belmont-Wagnor Mining Company's tramhouse next to the Ophir depot. While not showing the rear of the structure it was there that two openings permitted the cable supporting the ore buckets to enter the building. Ore was bagged then dumped into the cylindrical chute near the Rio Grande Southern tracks where it was loaded into boxcars for transport. The company didn't want their valuable ore transported in open top gondolas. Barely visible in the second photo is the counterweight next to the mountainside. This weight was used to keep tension on the tramway cable.

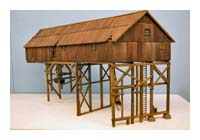

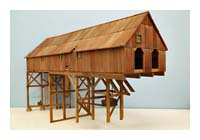

The above four photos show two different models of the Ophir tramhouse. The left shot by an unknown modeller and photographer includes a model of the Ophir depot. The next three display more detailed construction showing both the ore chute and the counterweight beneath the structure.