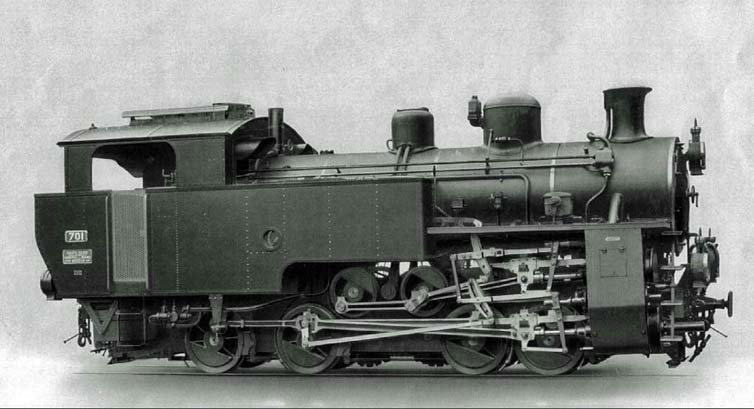

CLASS HG 4/4 HISTORY |

Built - 1924

Builder - Schweizerische Lokomotiv und Maschinenfabrik (SLM)

Boiler Pressure - 14 bar (203 psi)

Maximum Speed - Adhesion 40 kph (25 mph)

Maximum Speed - Rack 15 kph (9 mph)

Length - 8,950 mm (29.3 feet)

Weight Operating - 65 tons

Towing Capacity - 75 tons

Fuel - Coal

In 1923 the SLM (Schweizerische Lokomotiv und Maschinenfabrik - Swiss Locomotive and Machineworks) factory in Winterthur, Switzerland, constructed five HG 4/4 class rack steam locomotives, numbers 701 to 705. Then in 1929 the machine factory in Esslingen, Germany, delivered two similar locomotives numbered 706 and 707. These were war reparations from Germany to France for their losses during the First World War.

Until the Second World War there appears to be no records for these 9 locomotives. Then in 1947 the existing locomotives were given new numbers by the South Vietnamese State, VHX 40302, VHX 40303, VHX 40304, VHX 40306, and VHX 40308.

The four missing locomotives fate is unknown, but believed to be destroyed by the Viet Minh at the start of the first Indochina War in 1945-1946. These four original HG 4/4 locomotives, VHX 40301, VHX 40305, VHX 40307, and VHX 40309 were replaced by four ex-Furka Oberalp (FO) locomotives class HG 3/4 (numbers 201-204) procured in 1947 when the Furka Pass line was electriied.

Locomotives numbered VHX 40304, VHX 40306, and VHX 40308 survived the Vietnam War in more or less operational condition. After some war-related interruptions the last runs are known to have happened in 1975. The two SLM engines, VHX 40304 and VHX 40308, were stored at the Depot in Da Lat.

The Esslingen locomotive VHX 40306 was parked in the area of the railway workshops at the Thap Cham station. Occasionally it was used to provide warm water or as a steam generator. Many parts of the locomotive and body, as well as almost all valves, were missing on this locomotive by 1990.

When the Dampfbahn Furka-Bergstrecke (DFB) reactivated the Furka Pass line in Switzerland around 1990, apart from the four HG 3/4 locomotives in Vietnam, class HG 4/4 numbers VHX 40304 and VHX 40308 were brought back by the DFB to Switzerland in an unforgettable move bannered as "Back to Switzerland".

The remains of locomotive VHX 40306 had to be left behind in Vietnam for various reasons. The frame with the wheel sets, and the gear drive with the cylinder blocks eventually came to Switzerland via the port of Haiphong later in 1998.

In 2006 rebuilding of the two locomotives SLM 704 and SLM 708 by qualified specialists in the DFB workshop at Chur, Switzerland, returned 704 to its original configuration becoming operational in 2018 at Realp. As of 2020 SLM 708 remains in the Uzwil workshop with work being carried out as intensively as possible.

The locomotives had suffered greatly in past years as a result of the Vietnam War. Some maintenance work was carried out at Da Lat, although the infrastructure for larger work there was not available. So many parts were worn far beyond permissible limits. The locomotive frames were so badly damaged by the lack of maintenance that they could not be rebuilt by any reasonable effort, which was the initial intention. They had to be rebuilt using other still usable parts. This work was generously supported by the Stadler company. By the end of 2011 two new frames were riveted together by DFB staff at a workspace in Winterthur. Once the original frames were replicated they were transferred to the workshop at Chur.

Thus, with the "foundation" now available, it was possible to start rebuilding the remainder of the locomotives. Only where it was appropriate parallel work was carried out on both locomotives but otherwise 704 was the preferred engine. First the cylinder blocks and a new train and shock absorber devices (standard MGB/RhB) were installed so that riveting work on the frame could be completed. Despite 706 being available as a spare parts dispenser 704's left high-pressure cylinder and slide cover had to be re-cast. The necessary new construction plans were all created by volunteer DFB employees using CAD (Computer Aided Design) software.At the same time the elaborate repair and revision work on the boiler of locomotive 704 was carried out. Due to a better experience with the old riveted boilers, in comparison with replicated welded construction boilers, DFB decided to keep the old boilers. On the original boiler several parts had to be replaced. In 2013 at the newly acquired workshop in Uzwil, Switzerland, a new copper firebox was manufactured. The smokebox, including the smokebox pipe wall, had to be redone. Furthermore, new steam collecting boxes and back pressure brake housings had to be cast. The newly created copper firebox was installed in the revised boiler with the whole boiler work being carried out by DFB staff. The new water tanks as well as the cab and the coal box were also completed. Most fittings, either rebuilt or newly made, were then ready for installation.

In order for the locomotives to be able to negotiate the slightly tighter curves on the DFB without problems, some minor adaptations are required for both the locomotive and the track. On the locomotive side, the side play of drive axles 1 and 4 was increased. On the track side, adjustments are required at the point connections in Realp and Gletsch. Most of this work was carried out as part of the ongoing construction and maintenance program which was completed before the first HG 4/4 arrived at the railway.Once on the rails these powerful meter gauge cogwheel steam locomotives will become another distinctive feature of the Furka Pass route. Just one more reason to visit the Dampfbahn Furka-Bergstrecke to experience these exceptional Swiss locomotives.

Some data was loosely translated by Google with the addition of plausable corrections.